If you’re into survival knives, you know they’re more than just tools—they’re trusted companions in the outdoors. Part of that bond comes from making them your own, often by adding a mark, a name, or a logo. But when it comes to putting a lasting mark on your blade or handle, the big question is: which method is truly best for the job?

I’ve spent a fair bit of time looking into both laser engraving and silk screen printing. What I found is that the “best” choice isn’t universal. It comes down to what you value more: bold, colorful designs, or a mark that will literally last a lifetime through thick and thin.

In this guide, I’ll break down how each process works, where they shine, and where they might fall short for a survival knife. My goal is to give you the clear info you need to pick the right method for your blade.

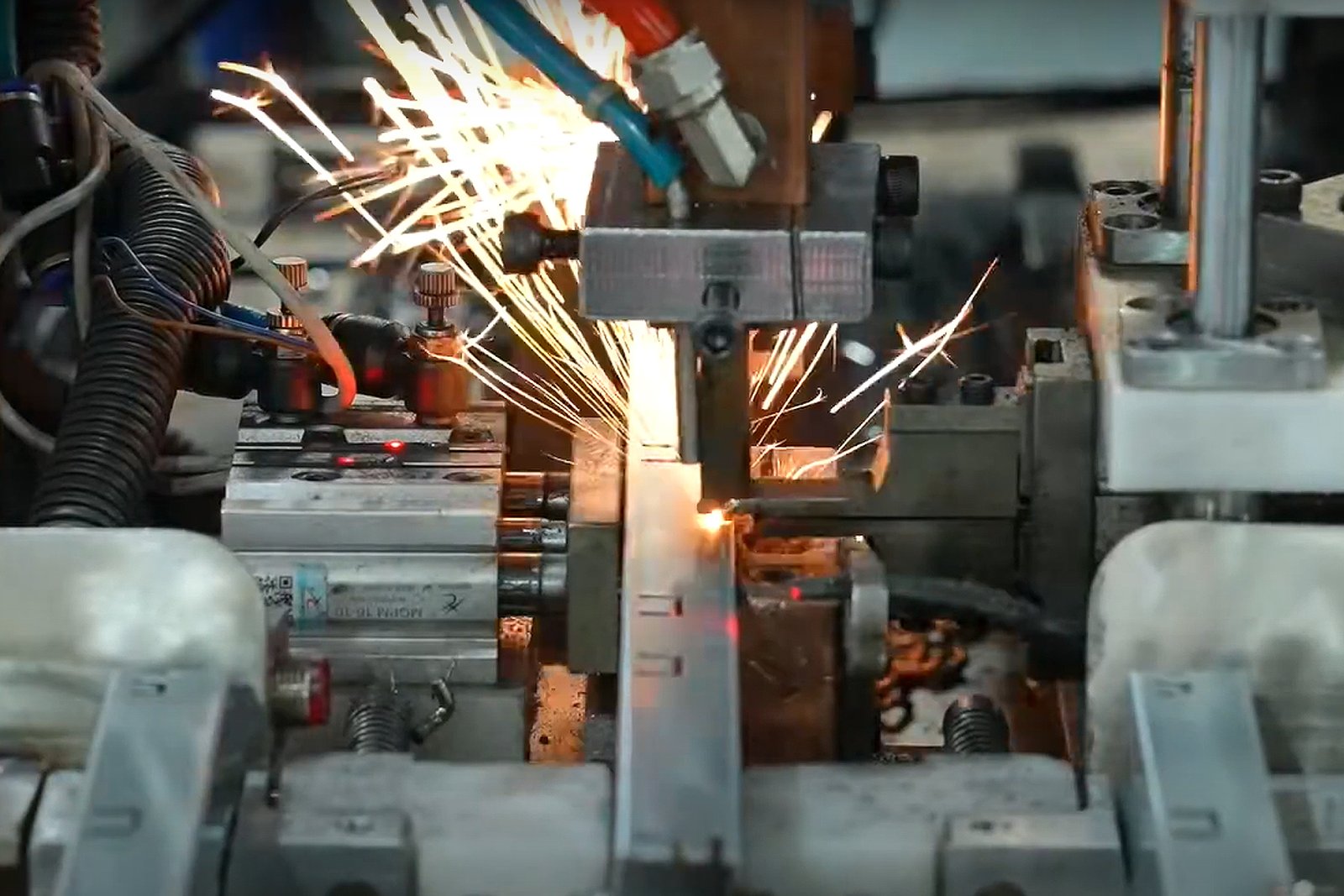

What is Laser Engraving, Anyway?

Let’s start with laser engraving, since it’s the high-tech option. In simple terms, it uses a highly focused beam of light to permanently alter the surface of a material. Think of it like using a concentrated sunbeam, but with incredible precision. The beam vaporizes a tiny layer of the material, leaving a clean, crisp, and permanent mark behind.

The coolest part? It’s a non-contact process. The tool never physically touches your knife. This means there’s no risk of slipping, scratching, or applying pressure that could distort a thin blade. You start with a digital design on a computer, and the laser follows those instructions perfectly every single time.

For knife work, two main types of lasers are used:

- Fiber Lasers:These are the go-to for marking metals like stainless steel, carbon steel, and titanium—so, perfect for your knife blade.

- CO2 Lasers:These are better suited for organic materials. They’re ideal if you want to engrave a wooden handle, a leather sheath, or composite handle materials(and are also capable of marking coated or painted metals commonly found on knife finishes, as noted by leading equipment manufacturers).

And What About Silk Screen Printing?

Silk screening, or screen printing, is the classic method. It’s a technique that’s been around for ages and is probably how your favorite graphic t-shirt was made. The process involves creating a stencil (or “screen”) for your design, placing it over the item, and then pushing ink through the fine mesh onto the surface below.

It’s a versatile method that can work on fabrics, glass, plastics, and metals. For a knife, you could use it to apply a logo or label. The results can be vibrant, with a thick, noticeable layer of ink that gives a great visual pop, especially with multiple colors.

Head-to-Head: The Survival Knife Showdown

So, how do these two stack up when applied to a survival knife? Let’s compare the key factors.

Durability & Permanence

This is the most critical category for a tool meant for hard use.

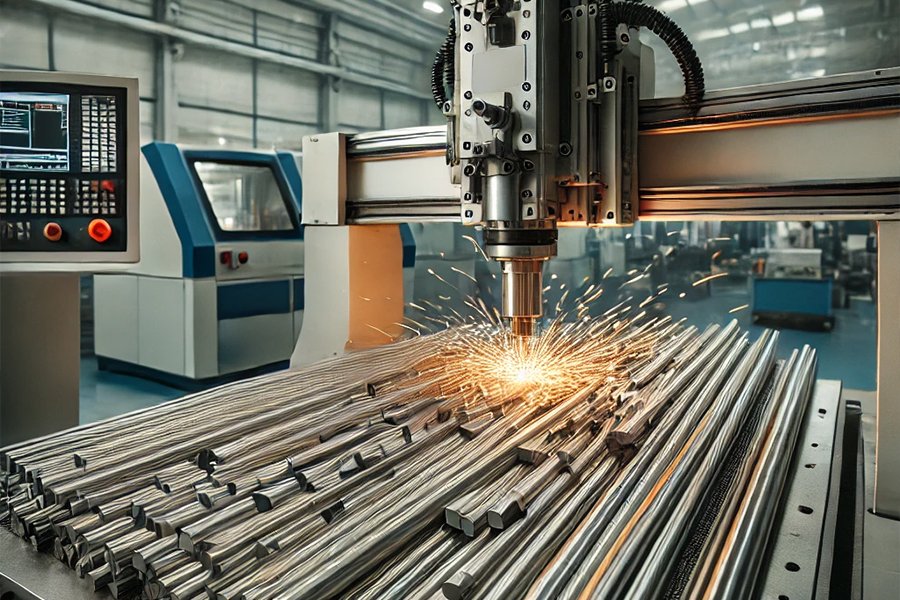

- Laser Engraving:The mark is permanent. It’s not a coating sitting on top; it’s a physical change to the material itself. This makes it highly resistant to abrasion, solvents, UV light, and extreme temperatures. You can scrub it, use it in the rain, or clean it with harsh agents—the engraving will remain legible. It becomes a permanent part of the knife.

- Silk Screen Printing:The durability comes from the quality of the ink. While modern inks are tough, they are still a layer on top of the metal or handle. Over time, especially with the scraping, handling, and exposure a survival knife endures, this ink layer can scratch, chip, or fade.

Precision & Detail

- Laser Engraving:This is where lasers dominate. They offer micron-level accuracy. Whether it’s a tiny serial number, an intricate topographic map, or fine text, the laser can reproduce it with sharp clarity. It can even handle curved surfaces on a blade or contoured handle with ease.

- Silk Screen Printing:While it can produce detailed images, its precision has limits, especially on a hard, curved surface like a knife. The process of aligning the screen and pushing ink can result in slightly softer edges compared to a laser’s crisp line.

Material & Design Flexibility

- Laser Engraving:Incredibly versatile. The same machine can mark your steel blade, engrave your walnut handle, and even etch your kydex sheath by simply changing the settings. There are also no limits on design complexity. Any digital graphic can be engraved, and changes are made with a click in software, making it perfect for one-off custom pieces.

- Silk Screen Printing:It works best on flatter, more uniform surfaces. Achieving a good print on the complex curves of a knife handle can be tricky. Each color in a design typically requires a separate screen and pass, which adds time and cost. Changing the design means creating a whole new screen.

Cost & Setup

- Laser Engraving:The initial investment in the machine is higher. However, for production, the operating cost is low. There are no physical screens, inks, or solvents to buy repeatedly. Once you have the digital file, you can engrave one knife or a hundred with consistent results and minimal extra cost.

- Silk Screen Printing:The startup cost can be lower for simple setups. But for production, costs add up: you need a separate screen for each design (and sometimes each color), ink, emulsion, and cleaning chemicals. It’s also more labor-intensive per item.

Environmental & Safety Factors

- Laser Engraving:It’s a cleaner process. Since it vaporizes material, it produces minimal waste (mostly captured by filtration systems). It doesn’t require inks, acids, or other consumable chemicals, making it a more eco-friendly and operator-safe choice.

- Silk Screen Printing:Involves chemicals for screen reclaiming and cleaning, as well as solvent-based inks. Proper ventilation and waste disposal are important considerations.

Real-World Scenarios: Which One Should You Choose?

So, when does each method make the most sense for your survival knife?

Choose Laser Engraving If…

- You want a permanent, wear-resistant mark like a serial number, maker’s mark, or owner’s initials that will survive a lifetime of use.

- Your design is highly detailed, intricate, or involves fine text.

- You’re personalizing a high-value, custom, or collectible knife where precision and permanence are paramount.

- You want to mark different materials (blade and handle) with the same setup.

- You value a clean, low-maintenance process without chemicals.

Choose Silk Screen Printing If…

- You need vibrant, full-color logos on a large, relatively flat surface (like a display case or the flat of a blade).

- You’re producing a larger batch of knives with the same, relatively simple design and want a cost-effective way to apply color.

- The tactile feel of a raised ink layer is part of the desired aesthetic.

- The knife is more for show or light use, where extreme durability of the mark is less critical.

Conclusion

After looking at all the angles, I have to lean heavily towards laser engraving as the superior choice for the vast majority of survival knife applications.

Why? Because the core virtues of a survival knife are reliability and durability. Every part of it should be built to last. Laser engraving aligns perfectly with that philosophy. It creates a mark that is as tough as the steel it’s etched into. This level of permanence isn’t just about durability; industry analyses suggest that such a permanent, wear-resistant mark can significantly enhance the perceived value and professionalism of the finished product.It won’t rub off when you’re processing kindling, won’t fade after years in the sun, and won’t chip if you scrape it against rock.

While silk screen printing has its place for colorful, graphic-heavy applications, its potential to degrade over time makes it a weaker link on a tool where failure is not an option. For a mark that honors the lifelong nature of a survival knife partnership—a mark that will tell its story long into the future—the precision and permanence of a laser are hard to beat.

In the end, your choice should reflect how you see your knife. Is it a display piece with bold graphics, or a functional heirloom with a permanent identity? For me, and for any knife destined for real adventure, the laser’s enduring touch is the clear winner.